INFRASTRUCTURE

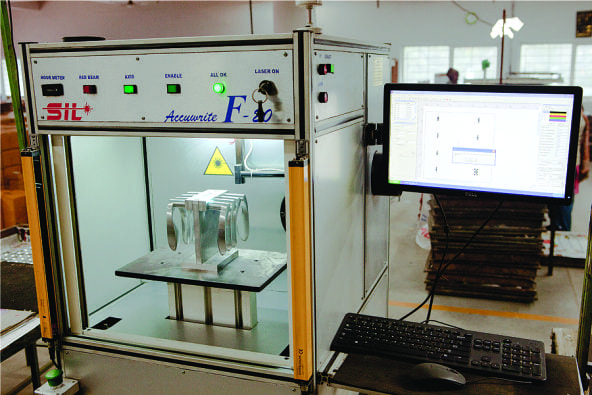

Our distinctiveness lies in the consolidation of all manufacturing processes within a single facility. This comprehensive setup includes sand and gravity casting, hot forging of brass, pressure die casting of zinc and aluminum, a machine shop equipped with CNC, a tool room featuring VMC, glass bead blasting, electroplating, electrophoretic lacquer, powder coating, laser engraving, assembly, and more. The presence of all these essential facilities contributes to expedited production and a swift turnaround time.